01

Tubing Systems/Pipe Fittings

Products Introduction

Tubing Systems /Pipe Fittings, as parts that connect pipes with pipes, which are hollow cylindrical or square components commonly used in various industries to transport fluids, support structural elements and encapsulate other components. The following are the standards, classifications and applications of pipes: standard: Pipe is manufactured and tested to specific standards set by organizations such as ASTM International, the American Society of Mechanical Engineers (ASME), the European Committee for Standardization (CEN), and other national and international standards bodies. Common standards for pipe include ASTM A53 for carbon steel pipe, ASTM A269 for seamless and welded austenitic stainless steel pipe, and ASTM A500 for structural pipe.

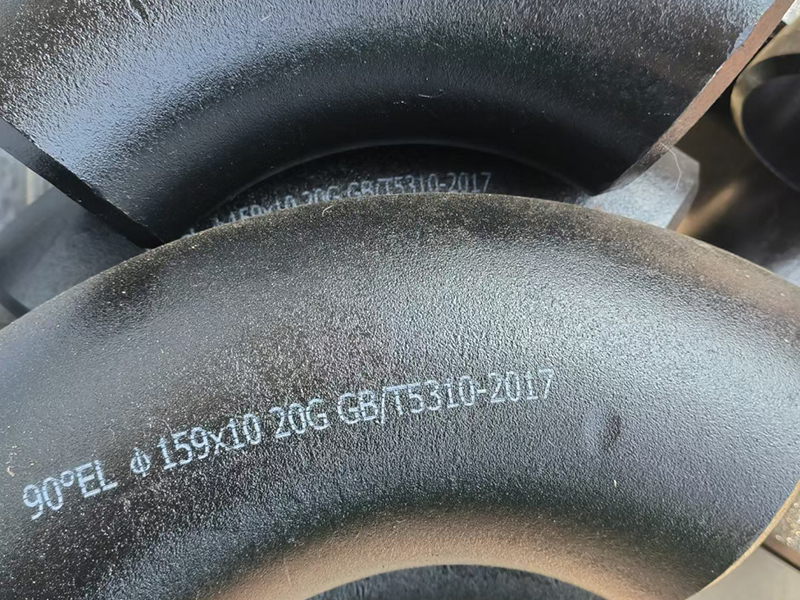

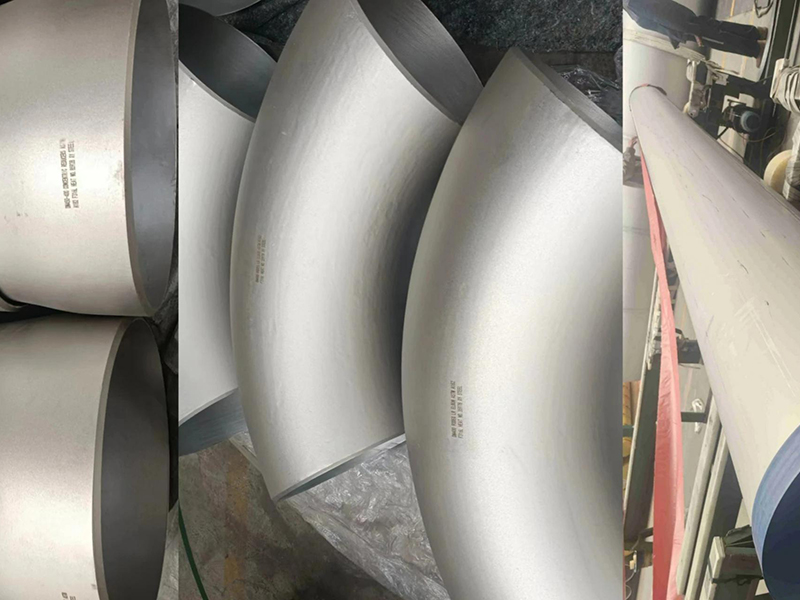

Classification: According to the connection method, it can be divided into socket fittings, threaded fittings, flange fittings and welded fittings. It is made of the same material as the pipe. There are elbow, flange, tee and reducer, etc. Elbows are used where pipes turn; Flange is used to connect the parts of one pipe and the other pipe, which is connected to the pipe end, and the tee is used for the place where three pipes converge; Reducers are used where two pipes with different diameters are connected.

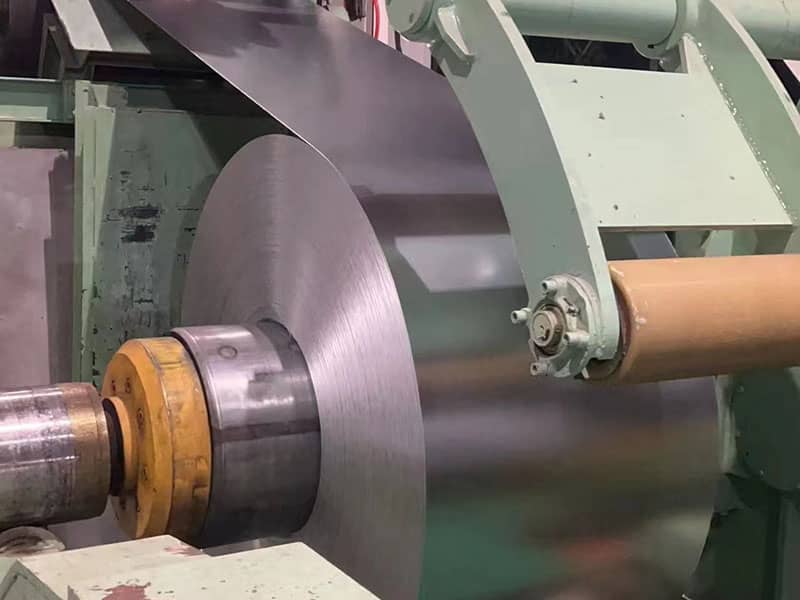

Manufacturing Methods: Pipes may be manufactured by processes such as seamless, welded, cold drawn, extruded, or other forming methods that affect the structural integrity and surface finish of the pipe. Sizes and Dimensions: Pipe is available in a variety of standard sizes, thicknesses and dimensional tolerances to meet specific industry requirements. End Connections: Pipes may have various end connections such as threads, flanges, welds, or other specialized fittings to facilitate installation and connection to other system components. application: Pipes have many applications in different industries, including but not limited to: Fluid Transportation: Pipelines are used in industries such as oil and gas, petrochemical, pharmaceutical and food processing to transport liquids, gases and other fluids. Structural Support: Pipes are used as load-bearing structural components in building construction, infrastructure projects, and mechanical framing. Heat exchange and refrigeration: Pipes are used in heat exchangers, condensers and refrigeration systems to transfer hot or cold fluids in industrial and HVAC (heating, ventilation and air conditioning)

Applications:

Automotive and Transportation: Due to its strength and corrosion resistance, tubing is used in vehicle exhaust systems, fuel lines, hydraulic brake lines and other automotive applications. Electrical and Electronics: Ducts are used as protective housing for wires and cables, as well as to house electronic components in a variety of applications. Factors such as material compatibility, pressure rating, temperature resistance and environmental conditions should be carefully considered when selecting pipe for a specific application. Additionally, compliance with relevant standards and regulations is critical to ensuring that pipelines meet the safety and performance requirements for their intended use. Pipes play a critical role in numerous industries, providing essential components for fluid handling, structural support, and other critical functions. If you need more details about a specific type of pipe, its properties, or applications, feel free to ask for more information!

Standard and Steel Grade:

ASME/ANSI B16.9, ASME/ANSI B16.11, ASME/ANSI B16.28

ASME B16.5

MSS SP-43, MSS SP-75, MSS SP-79,MSS SP-83, MSS SP-95, MSS SP-97,

JIS B2311, JIS B2312, JIS B2313, JIS B2316

ASME SA-234, ASME SA-420, ASME SA-403,

ISO 5251,

DIN 2605, DIN 2615, DIN 2616, DIN 2617

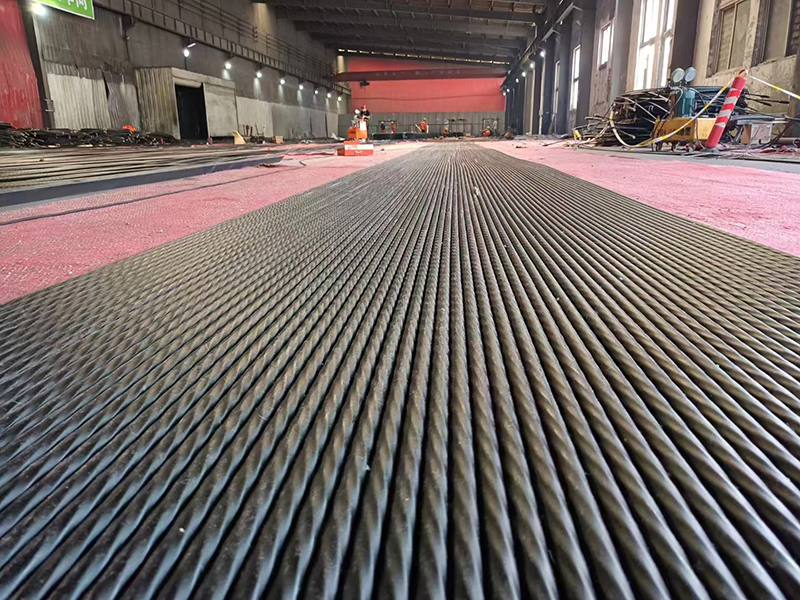

Workshops and Production Equipment

010203040506070809