01

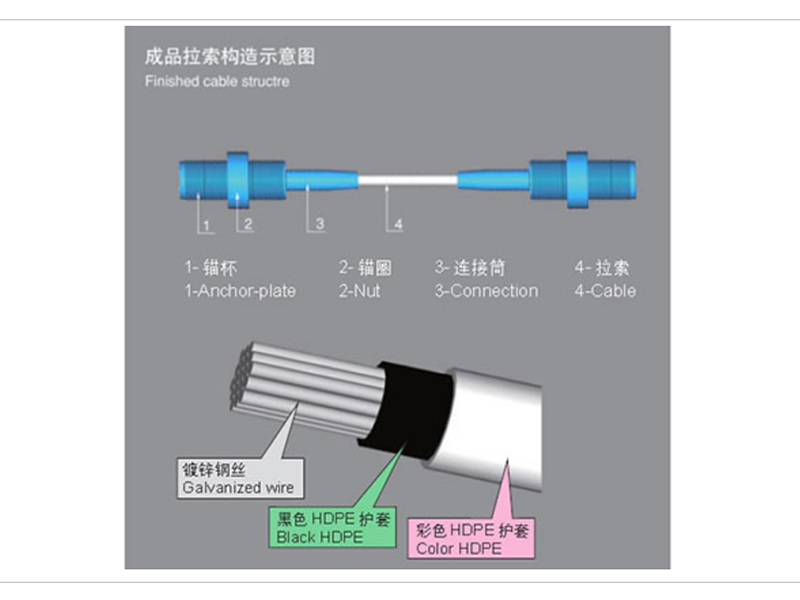

Polyethylene Covered Stay Cable/Galvanized parallel wire cable

Introduction

France released the NFA-35-035 "Hot-dip galvanized and zinc aluminum alloy prestressed steel wire and steel stranded wire". The standard covers the nominal diameter of 5.0mm, 6.0mm, 7.0 mm and suspension bridge respectively. The main technical indicators of the galvanized / zinc aluminum alloy coated steel wire are shown in the table.

Structures

They consist of load-bearing plates, wedge plates and wedges. Insert the tendon into the anchor and drive a wedge into the wedge plate to clamp the tendon in place. Plane stress anchors are available in different configurations, such as single-strand anchors for a single steel bar and multi-strand anchors for multiple bars. They are critical to ensuring the effective transfer of prestress to the concrete, providing the structural integrity required for the application.

Mechanical properties of galvanized / zinc aluminum alloy coated steel wire

|

Dia./ mm |

Tensile Strength /MPa |

Breaking Force Fm/kN |

The limitate load at 0.1%inelasticity strain 0.1% FP0.1/kN |

Elongation rate after breaking /% |

Relaxation Rate /% |

|

5 |

1 770 |

34.8 |

31.0 |

3.5 |

The relaxation rate was 2.5 after 1000h |

|

1 860 |

35.5 |

32.5 |

|||

|

6 |

1 670 |

47.3 |

42.0 |

||

|

1 770 |

50.1 |

44.5 |

|||

|

7 |

1 670 |

64.3 |

57.0 |

||

|

1 770 |

68.1 |

60.6 |

Features

Steel wire is divided into Class A and B. Class A steel wire is mainly used for prestressed products with small safety factor and small live load. Its fatigue resistance requires 0.70σb stress limit and 200 MPa.and 2 million cycles. Class B steel wire is mainly used for bridge cables with large safety factor and large live load. Its fatigue resistance requires 0.45σb with stress amplitude of 300 MPa and 2 million cycles. At the same time, the standard also stipulates the number of repeated bending of the wire to test the plasticity of the wire.

Advantageous

Bridge cable is the lifeline of a large-span suspension bridge or cable-stayed bridge across the sea and the river. The corrosion resistance of its steel wire is very important for the durability and safety of the structure. The standard divides the coating performance of the steel wire into four categories:

(1) the quality of the coating per unit area of the steel wire;

(2) the attachment strength of the coating;

(3) the continuity of the coating; and

(4) other aspects. The standard requires that the quality of the coating surface per unit area of the steel wire should be 180~350 g / m2, the density of the coating is calculated according to 7.2 g/cm3, and the thickness of the coating should be 26~49μm. The inspection method of quality of steel wire coating per square meter shall be NF EN1460, and the length of test sample shall not be less than 150 mm.The polyethylene Covered stay cable/Galvanized parallel wire cable is produced by twisting high strength galvanized steel wire and then coating the twisted wire with high-density polyethylene with a hot extrusion process. lt is widely used as cable for cable stayed bridge,tie-down cable,hanger for orch bridge, suspender for suspension bridge and cable for special struduer.

Cable of wind-rain vibration suppression

The stay cable is one of the vital components of cable-stayed bridges and they are prone to vibration as their lengths increase.These cables are designed to minimize vibration caused by wind.This extends the working life of the bridge and provides added safety.

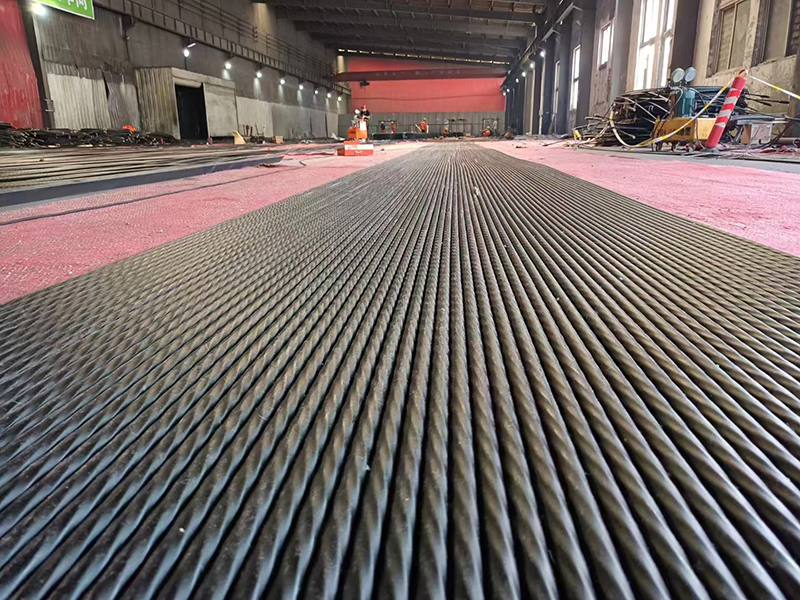

Cable with double helical wire

The double helical wires on the stay cable surface with the defined height and pitch prevent the rain wind induced vibration.This technology has been successfully applied to bridge projects,such as Edong Yangtze River Bridge, Shenzhen Bay Bridge, Indonesia Suramadu Bridge, Jinan Jianbang Bridge and soon.

Ultra high strength durable cable

On the basis of common stay cable, the ultra-high-strength durable (strength grade up to 1770MPa,1860MPa and 1960Mpa) cable has been extended it is service life over 50-years under normal condition by using better raw material, improving manufacturing techniques and cable structure.

lt has been used on Sutong Bridge,Hong Kong Stonecutters Bridge, Zhujiang Huangpu Bridge, JiashaoBridge, HongKong-Zhuhai-Macau Bridge etc.

Ultra long and large cable

With the construction of cable-stayed bridges with its main span longer than 100m,the requirements for stay cable become higher and higher in length and performance.At present, our company can manufacture ultra-long and large stay cable with the length over 800m and the biggest size can reach511p7.We are the only professional manufacturer which has the ability to produce cable longer than500m.