01

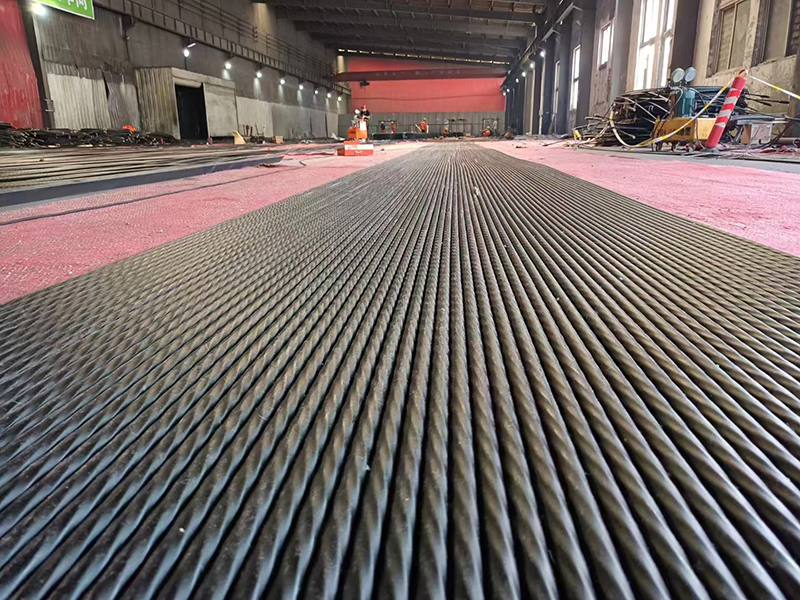

Hot-Dip Galvanized Unbonded Steel Strand

Product Introduction

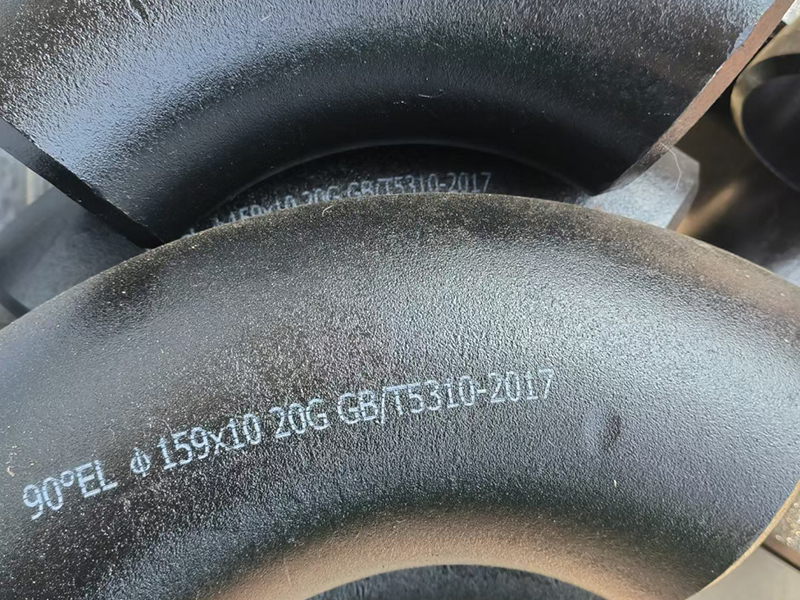

PC-strand,galvanized-greased-PE-coated (referred as Hot-dip galvanized unbonded steel strand) is an important construction and engineering material that provides strong and durable performance for a variety of applications. The hot-dip galvanizing process involves dipping steel strands into molten zinc to provide a protective coating, creating a durable and corrosion -resistant coating inside and surface of pc strand.

These strands are "bondless," meaning they don't bond to the surrounding concrete, allowing for greater flexibility and mobility. Due to its high tensile strength and corrosion resistance, this type of strand is commonly used in construction applications such as post-tensioning and prestressed concrete structures.

Product Features

1)Performance and applications Corrosion Resistant:

Hot-dip galvanized coating provides excellent protection against corrosion, making steel strands particularly suitable for applications in harsh environments such as marine construction, bridges and coastal structures.

2)High tensile strength:

These steel strands have high tensile strength, making them ideal for prestressed and post-tensioned concrete structures. They provide structural stability and support for a variety of construction projects.

3)Flexibility:

Unbonded strands provide greater flexibility and movement within concrete structures, making them suitable for dynamic loading environments, seismic areas and applications where movement and stress need to be accommodated.

4)Longevity:

Galvanized coating extends the service life of steel strands, helping to increase the durability and resiliency of structures using steel strands.

Product Applications

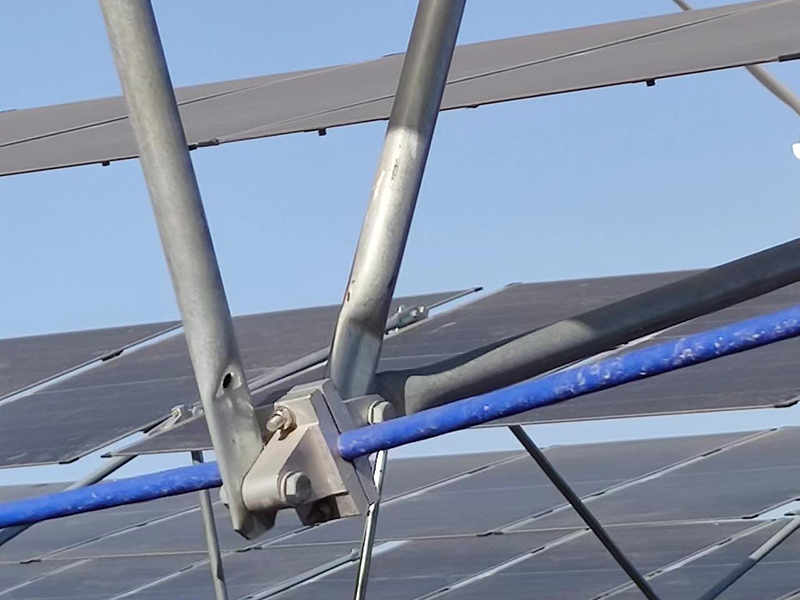

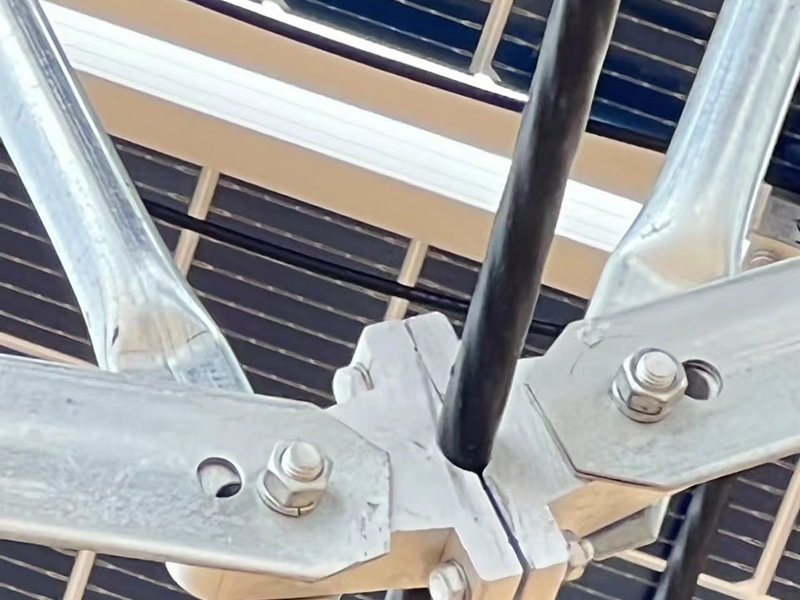

The resulting products are widely used in construction, civil engineering and infrastructure projects due to their corrosion resistance, high tensile strength and flexibility.

Applications: Hot-dip galvanized unbonded steel strands are commonly used in a wide range of applications including bridge construction, high-rise buildings, railway ties, nuclear power plants, and other civil engineering and infrastructure projects.

Product Advantages

1)Durability:

A protective galvanized coating significantly extends the life of the strand, reducing maintenance costs and improving long-term performance.

2)Corrosion Protection:

Galvanized coatings act as a barrier, protecting steel from moisture, chemicals, and environmental factors that can cause corrosion and degradation.

3)Reduced risk of breakage:

The high tensile strength of steel strands, combined with the flexibility provided by a bondless design, minimizes the risk of breakage and ensures structural integrity.

4)Versatility:

Hot-dip galvanized non-bonded steel strand is versatile and can be customized to specific project requirements and is available in a variety of diameters, tensile strengths and surface finishes.

In conclusion, Hot-dip galvanized unbonded steel strand plays a vital role in the construction and engineering industries providing strength, durability and corrosion resistance. Their use in prestressed and post-tensioned concrete structures helps improve the safety, longevity and performance of a variety of infrastructure projects. With their versatility and high-quality finish, these strands continue to be in demand for a wide range of construction applications.