01

Hot - Dipped Galvanized Prestressed Steel Strand

Product Introduction

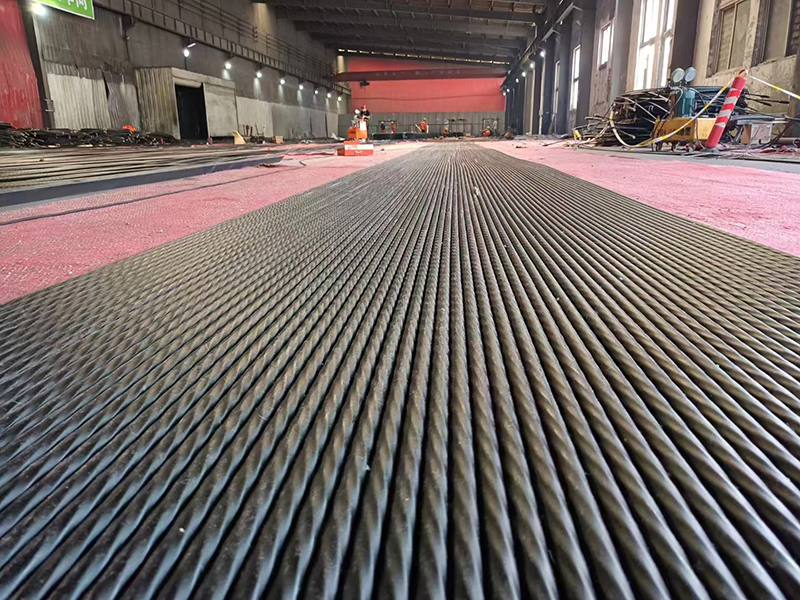

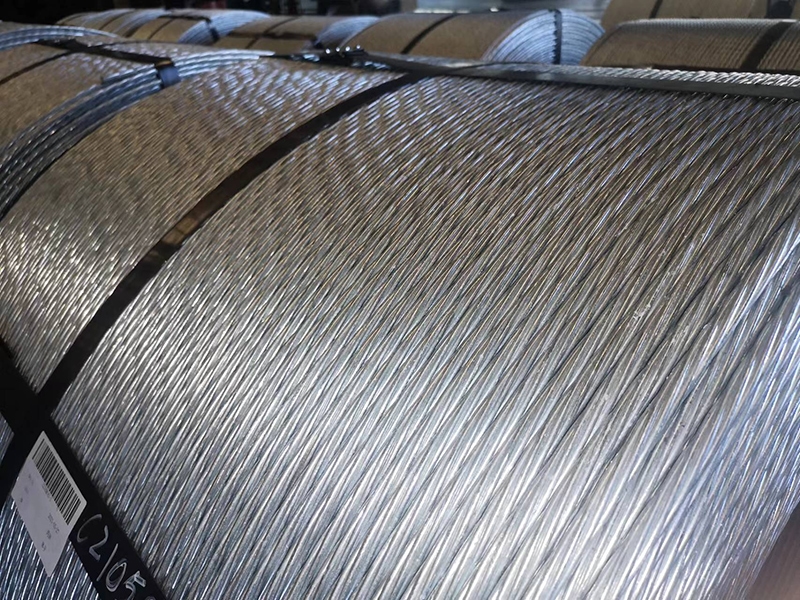

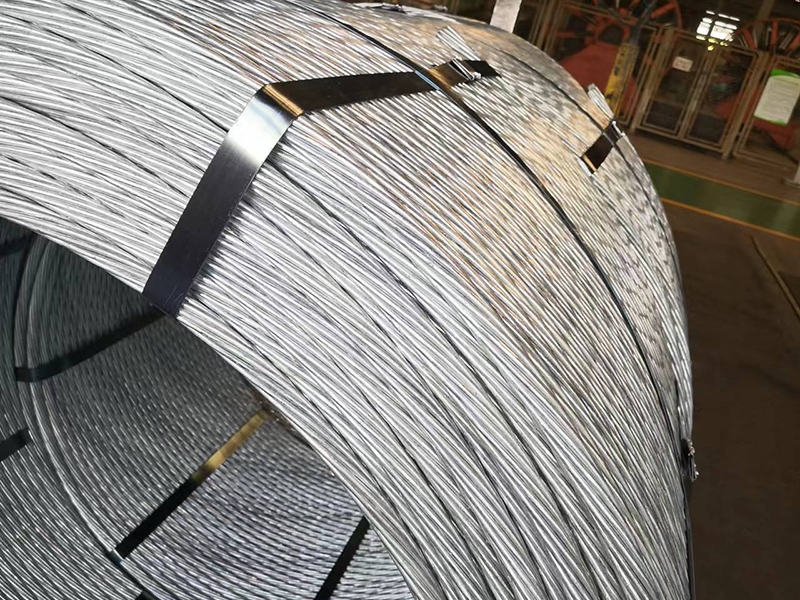

Hot-Dipped Galvanized PC Strand low relaxation prestressed steel strand is made of seven hot- dipped galvanized round steel wires with good corrosion resistance, which can effectively extend the life of components in the state of corrosive environments such as coastal areas, which are recognized as an effective form of corrosion prevention in currently and internationally.

This standard is applicable to bridge cable, fixed tension components, lifting or fixing tension parts of buildings and other prestressed structures,which is not directly used in concrete grouting constructions, diameter: 12.7mm, 15.mm, 15.7mm, 17.8mm, strength class: 1770MPa, 1860 MPa, 1960MPa. (hereinafter referred as "steel strand").

The structure of 1x7, 1x19 hot-dipped galvanized prestressed steel strand series products, the tensile strength which can reach 1860MPa and same specifications as plain&round PC steel strand in terms of performance levels acc.to GB/T 33363, ASTM A416, EN10138, BS5896 and NFA35-035 etc.

Product Features

The product can be produced as per the requests of zinc coating from customers, zinc coating can reach to 250 gsm or above, the uniformity of zinc coating layer is 3-4 times without exposing copper, and the adhesion does not break and does not peel under the condition by winding 8 circles after zinc coated .

Depending on the company's advanced equipment, we can design the galvanized process to meet the special requirements of users on zinc layer quality, surface quality, etc.

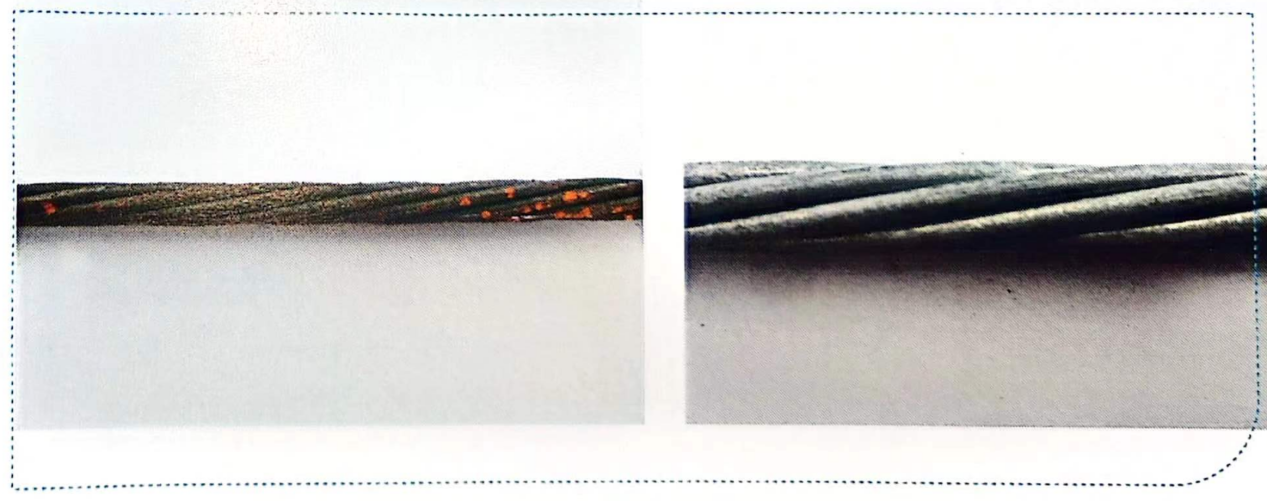

Comparing with PC steel strand without coating and galvanized PC steel strand, the former appeared red rust after salt spray test for 24 hours.

Sample changes of PC steel strand without coating and galvanized PC steel strand after 21 days of neutral salt spray test as follows,

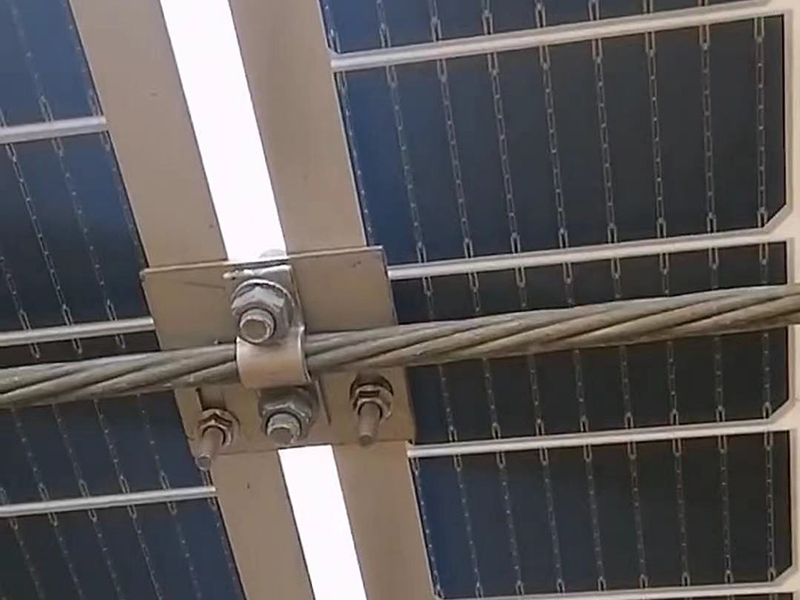

Product Applications

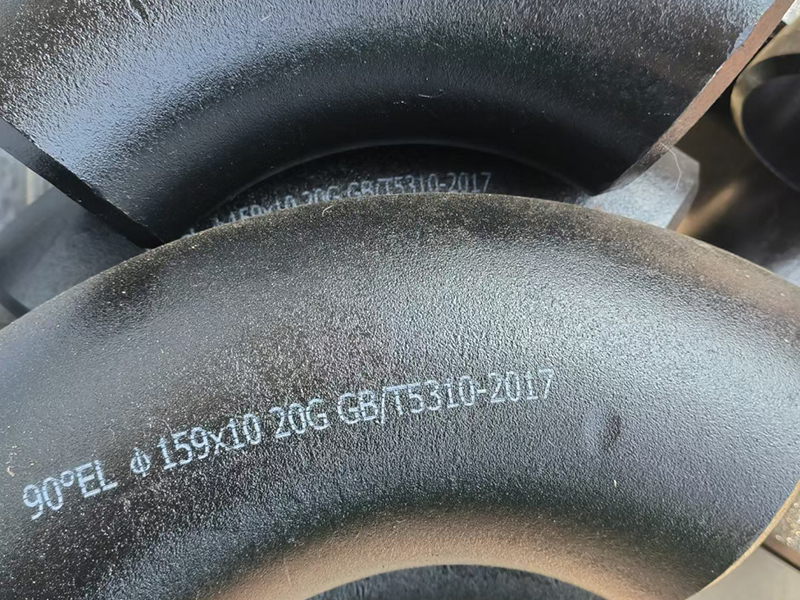

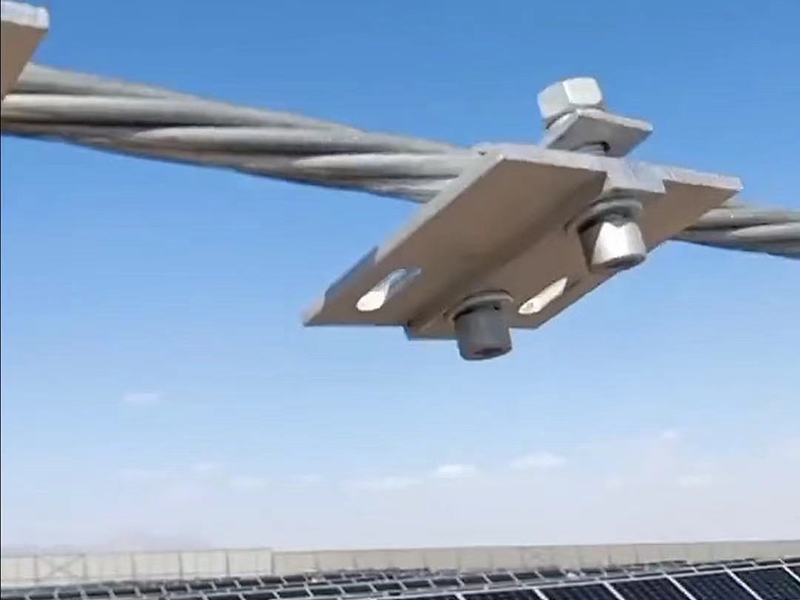

1)The products can be used in construction engineering and coal mine roadway support engineering under harsh environmental conditions.

2)In recent years, it has also been applied in the field of wind power. "1x7-medium 21.6mm, Large-Sized Hot-Dipped Galvanized PC Steel Strand", which applied in the world's first "160m, low-wind-speed prestressed frame wind turbine tower", with high carrying capacity,which is conductive to improve the wind resistance of the tower. With good corrosion resistance,which can extend the service life of the tower.

The world's first 160m low wind speed experimental high tower in Shandong

Specifications of Hot-Dipped Galvanized Steel Strand (Ref.standard GB/T33363-2016)

1) Deviations of Dimensions,Area,Weight,Wire Dia.and Strand Dia.

| Nominal Dia. (mm) | Cross-section Area (㎟) | Reference Weight per Meter (g/m) | Difference Between Center wire and Outer wire (min.mm) | Deviation of Strand Dia. (mm) |

| 12.7 | 98.70 | 771 | 0.08 | ﹣0.15 ﹢0.30 |

| 15.2 | 140.0 | 1093 | 0.11 | ﹣0.15 ﹢0.40 |

| 15.7 | 150.0 | 1172 | 0.12 | |

| 17.8 | 191.0 | 1492 | 0.15 | |

| Note 1: The nominal diameter, nominal cross-sectional area and reference weight per meter of the steel strand included with zinc layer. Note 2: The density of the steel strand is 7.810g/cm3. | ||||

2) Mechanical Properties of Hot-Dipped Galvanized Steel Strand

Nominal Dia. (mm) |

Strength Mpa |

Maximum Force F min/kN ≥ |

Non-proportional Extension Force Fp0.2 / kN ≥ |

Relaxation Rate after 1000.h (Initial load 0.7 Fm) r/% ≤ |

12.7 |

1770 |

175 |

156 |

2.5 |

1860 |

184 |

164 |

||

1960 |

193 |

172 |

||

15.2 |

1770 |

248 |

221 |

|

1860 |

260 |

231 |

||

1960 |

274 |

244 |

||

15.7 |

1770 |

266 |

237 |

|

1860 |

279 |

248 |

||

1960 |

294 |

262 |

||

17.8 |

1770 |

338 |

301 |

|

1860 |

355 |

316 |

||

1960 |

374 |

333 |

||

Note1:The Elastic modulus of hot-dipped galvanized steel strand must be(195±10)Gpa. | ||||

Note 2: Elongation at Max.load not less than 3.5%(Lo≥500mm,Agt≥3.5%) | ||||

Note 3: Zinc Coating: 190~350 (g/㎡) | ||||