01

Piling Pipes

Products Introduction

Material standards:

Piling pipes are typically classified based on the material they are made of, which can include carbon steel, alloy steel, or other materials. Specific material standards will depend on the intended application and the environment in which the piling pipe will be used.

Manufacturing Standards:

The manufacturing process of piling pipe may require compliance with specific standards to ensure the quality, reliability and performance of the pipe. These standards may be developed by organizations such as the American Society for Testing and Materials (ASTM), the American Petroleum Institute (API), or other relevant national or international standards bodies.

Design Standards:

Piling pipes may be required to meet certain design standards to ensure their structural integrity and load-bearing capacity. These standards may be developed by engineering and construction organizations or government regulatory agencies.

Manufacturing standards:

The manufacturing process of Submerged-Arc Welded Steel Pipes can follow the specific standards set by organizations such as the American Petroleum Institute (API), the American Society for Testing and Materials (ASTM), or other national or international standards organizations as follows: API 5L, API 5CT, ASTM 53, EN10217, DIN 2458, IS 3589, GB/T3091, GB/T9711,EN10217, EN10219

Application Criteria:

Piling pipes can be classified according to their intended use, such as marine piling, foundation piling, or specific types of soil or geological conditions. It is important to consult the specific standards and classifications associated with the type of piling pipe required for a particular project. If you have specific criteria or classifications, please feel free to provide more details so I can provide more targeted information.

Process:

SSAW - Spiral Submerged arc welded

LSAW – UO(UOE)、RB(RBE)、JCO(JCOE)

DSAW - Double Submerged arc welded

Dimensions:

Out Diameter: 355.6mm– 1626mm

Wall Thickness: 8 -50mm

Length: up to 12m

Steel Grade:

API 5L: GR B, X42,X46, X56, X60,X65,X70

ASTM A53: GR A, GR B, GR C

EN: S275, S275JR, S355JRH, S355J2H

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360- L555

Surface: Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test.

Mill Test Certificate: EN 10204/3.1B

Application Criteria: Longitudinal welded pipes can also be classified based on its intended use, such as oil and gas pipelines, structural applications, or general industrial use. Be sure to refer to the specific standards and classifications relevant to your specific requirements, as they may vary based on industry and region.

API 5L Line Pipe

API 5L PSL1/PSL2 GR B , X42, X46, X52, X60, X65, X70

MECHANICAL PROPERTIES AND STEEL CHEMICAL COMPOSITION

|

STEEL GRADE |

Yield strength, min. psi (MPa) |

Tensil strength, min. psi (MPa) |

Elongation in 2 in., min. % |

|

GR B |

245 |

415 |

|

|

X42 |

290 |

415 |

|

|

X46 |

320 |

435 |

|

|

X52 |

360 |

460 |

|

|

X56 |

390 |

490 |

|

|

X60 |

415 |

520 |

|

|

X65 |

450 |

535 |

|

|

X70 |

485 |

570 |

|

STEEL GRADE |

% by mass, Maximum |

||||

|

C |

Si |

Mn |

P |

S |

|

|

GR B |

0.26 |

0.40 |

1.20 |

0.030 |

0.030 |

|

X42 |

0.26 |

0.40 |

1.30 |

0.030 |

0.030 |

|

X46 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X52 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X56 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X60 |

0.26 |

0.40 |

1.40 |

0.030 |

0.030 |

|

X65 |

0.26 |

0.40 |

1.45 |

0.030 |

0.030 |

|

X70 |

0.26 |

0.40 |

1.65 |

0.030 |

0.030 |

STEEL PIPES AS PER ASTM A53 GR. B

MECHANICAL PROPERTIES AND STEEL CHEMICAL COMPOSITION

|

STEEL GRADE |

Composition Max, % |

||||||||

|

C |

Mn |

P |

S |

Cu |

Ni |

Cr |

Mo |

V |

|

| GR B |

0.30 |

1.20 |

0.05 |

0.05 |

0.40 |

0.40 |

0.40 |

0.15 |

0.08 |

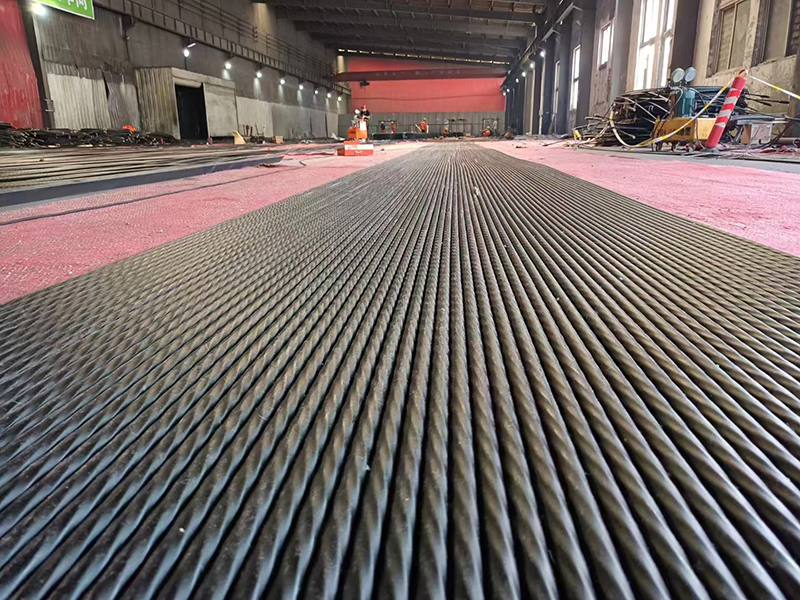

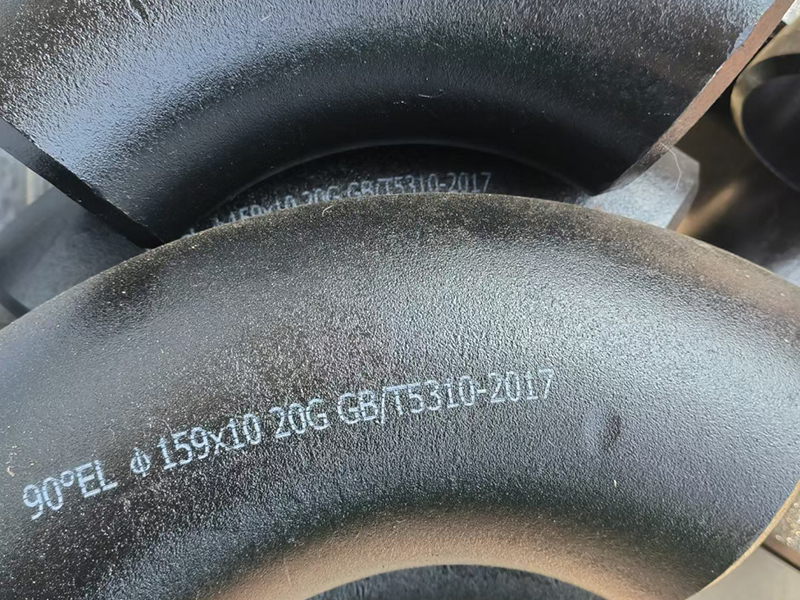

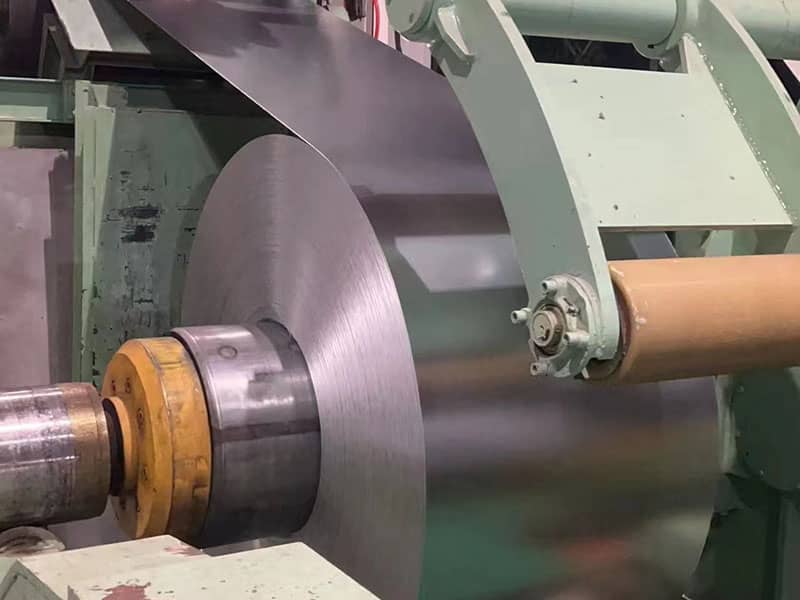

Workshops and Production Equipment

010203040506070809